The electrical asset oil is subjected to electrical stress and high-temperature variations, as well as chemical pollution, throughout its operating cycle. Without a check on given parameters, power outages might occur. Regular transformer oil testing is critical for maintaining and extending life of the transformer and avoiding major failures. The oil tests for other assets such as Circuit Breakers and Chillers are used to determine their performance. The IEEE standard is used to describe transformer oil's general electrical and physical qualities.

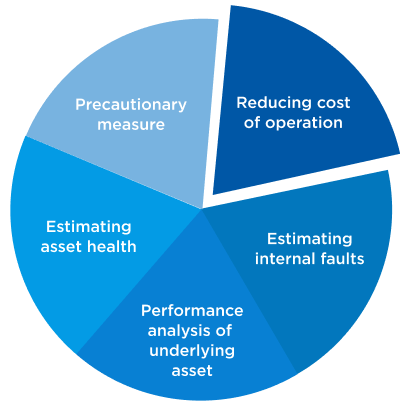

The apparent objective for doing oil testing is to determine the state of the oil, and the oil analysis is meant to shed insight on the condition of the underlying asset.

This is concerned with determining the oil's present physical and chemical status as well as its Remaining Usable Life (RUL). It help us in determining the basic oil specifications and help in analysing with the standards set by NABL

This helps in finding the contamination in the oil which can lead to sludge formation. This helps in analysing the sources of the contamination which can be internal or external. Identifying the existence of damaging pollutants and narrowing down their likely origins helps to take proper measures to increase the usable life of the asset.

The National Accreditation Board for Testing and Calibration Laboratories (NABL) is an autonomous organization registered under the Societies Act 1860 and overseen by the Department of Science and Technology of the Government of India.

The Major advantage of testing through a NABL Accredited lab is that it helps in improvement in the performance of oil tests/calibrations following investigation and identification of the cause(s) of unsatisfactory performance, and the introduction of corrective action to prevent re-occurrence. Also the Staff education, training, and competence & Evaluation of methods, including the establishment of method precision and accuracy of oil test results monitoring by NABL report analysis. This helps in standardized results and reports for improved decision-making.

Motwane Manufacturing Private Ltd. acquired Transgear Oil Testing Lab in the year 2021. The Oil laboratory is NABL accredited and believes in providing the best possible value to the customers through continuous upgradation and advancement in best practices. Since the acquisition, Motwane has revolutionized the oil testing processes and analytics that go beyond just reporting parameter results.

With the introduction of the analytical solutions, Motwane Digital aspires to handhold the industry in the world of digital to reap the power of data.

Saves money by reducing inefficient, time-consuming maintenance

Securely increases the time between maintenance treatments.

Predicts present status and detects degradation before asset fails

Advanced analytics which helps in CapEx planning and helps in audit compliance

Helps in assessing the health Status of the asset with the help of basic tests conducted.

Analytical models which helps in assessing in the expected residual life of the asset which inturn helps in better CapEx planning.

Certified IEEE models, helping in condition assessment of the paper insulator in the windings of the transformer.

Centralized data storage helps in assessing the trend of parameters that enables Root-Cause Analysis (RCA).

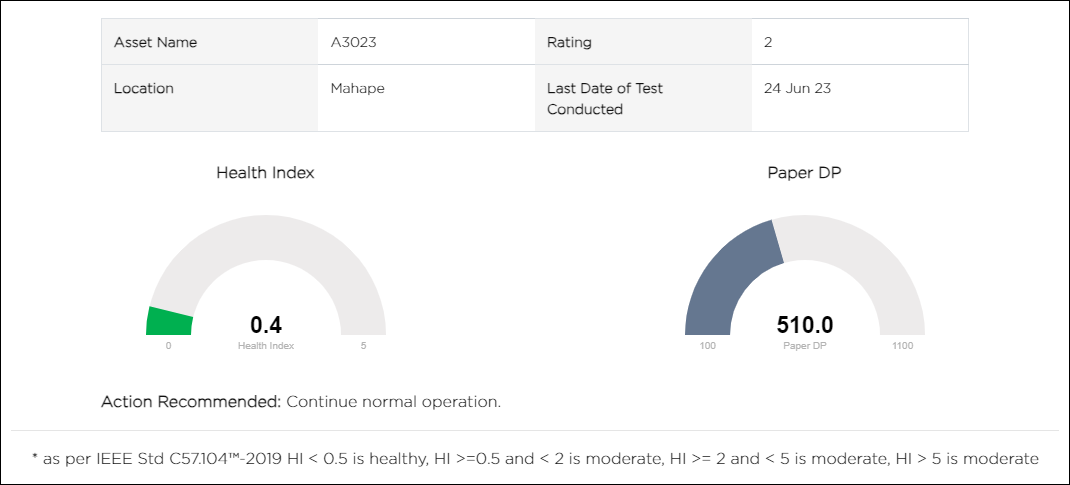

In our analytical models through Machine Learning, the customer gets a health card for each transformer which gives the operator and the field engineers actionable insights to improve performance as well as avoid any major breakdown of the transformer.

The most cost-effective and safe proven technique for oil extraction, with minimal effect on the operations

Our NABL accredited lab operates best in the class equipment with cutting edge technologies to provide highly accurate results

Advanced models to determine the health of the assets with recommendations consisting actionable intelligence